As temperatures begin to drop, proactive fall maintenance for your commercial HVAC system isn’t just recommended—it’s essential for avoiding costly winter breakdowns and keeping your business running smoothly. Neglecting seasonal upkeep can lead to inefficient heating, higher energy bills, and unexpected repairs that disrupt operations. In this guide, we’ll cover key fall maintenance tasks—from inspecting heat exchangers to calibrating thermostats—so you can optimize performance, improve indoor air quality, and extend the lifespan of your system before the busy winter season arrives.

How to Prep Your Commercial HVAC for Fall Efficiency

Why Is Fall HVACMaintenance Crucial for Commercial Buildings in Metro Atlanta?

Fall maintenance is the simplest way to keep heating equipment reliable when the first cold front arrives. A thorough tune-up in autumn covers inspection, cleaning, and calibration before workloads climb. The payoff is steadier indoor temperatures, fewer surprise service calls, and lower utility spend through the winter. For example, a Buckhead restaurant that scheduled a pre-season furnace check avoided an opening-night outage when temperatures dipped. Facility teams that already coordinate vendors can fold HVAC checks into the same fall readiness plan and reduce operational friction.

How Does Atlanta’s Fall Climate Impact Commercial HVAC Systems?

Atlanta’s shoulder season swings from warm afternoons to cool nights. That back-and-forth forces frequent mode changes on rooftop units and heat pumps. Moist air can condense inside ducts and on coils, which invites corrosion and microbial growth if filters and drain lines are neglected. Rapid cycling stresses contactors, bearings, and belts. Refrigerant control can drift as ambient conditions change, which shows up as longer runtimes and uneven comfort. Addressing these items in fall keeps equipment stable before sustained cold loads arrive and prevents small issues from turning into downtime during peak hours.

What Are the Energy Efficiency Benefits of Fall HVAC Maintenance?

Cleaning heat exchangers and coils improves heat transfer, so the system reaches setpoint faster and runs fewer minutes per hour. Verifying refrigerant charge and superheat keeps compressors in their efficient operating window. Balancing supply and return airflow and replacing loaded filters reduces fan energy and eliminates hot and cold spots that trigger thermostat overcorrection. In typical multi-tenant or retail buildings, these basics deliver about 5 to 15 percent savings on heating costs through winter. Controls checks matter too. Economizer dampers that actually close, accurate sensor calibration, and realistic morning warm-up schedules prevent needless reheat and trim demand charges. Documenting these adjustments in the work order gives you a baseline to compare against monthly bills.

How Does Regular Maintenance Extend HVAC System Lifespan?

Wear accumulates when parts run dirty or out of spec. Lubricating blower bearings, tightening electrical connections, and replacing weakened contactors reduce heat buildup and arcing that shorten motor life. Clearing condensate lines stops water from backing into equipment and damaging cabinets and insulation. Verifying combustion on gas furnaces protects heat exchangers from soot and cracks. Small parts like belts and filters are inexpensive compared with premature compressor or motor replacements. Buildings that complete a full fall checklist often add 2 to 3 years of useful life to rooftop units, which delays capital spend and stabilizes the maintenance budget.

What Should a Practical Fall Checklist Include?

Keep it simple and consistent. Inspect burners or heat strips, clean indoor and outdoor coils, check refrigerant pressures against manufacturer targets, confirm defrost on heat pumps, calibrate thermostats and zone sensors, replace filters, test safeties, and review trend data in your building automation system. Walk the roof for panel gaps, hail damage, and loose conduit. Inside, confirm airflow at problem suites and verify that economizers and outside air dampers move freely. Log findings with photos and measured values so the next visit can track drift over time.

What Are the Key Components of a CommercialHVAC Fall Tune-Up?

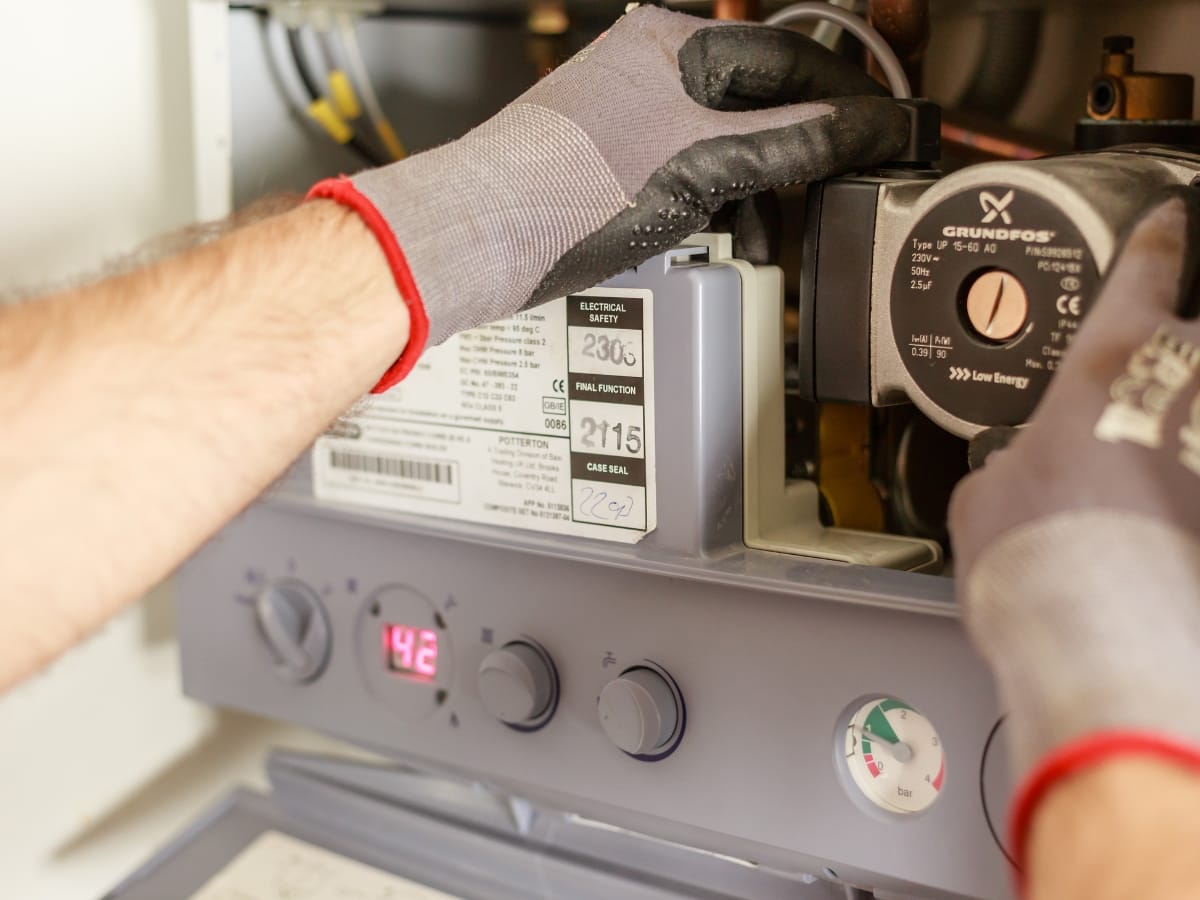

A solid fall tune-up for commercial HVAC systems starts with a safety and visual inspection. Technicians confirm clearances, check panels and gasketing, and look for signs of water intrusion or corrosion. Next comes airflow and filtration. Filters are inspected, replaced, or upgraded, and supply and return airflow is measured so fans are not fighting blockages. Refrigerant circuits and heat exchangers are then evaluated. Coils are cleaned, refrigerant pressures and temperatures are recorded, and heat exchangers are checked for cracks or soot. Electrical and controls testing follows, including tightening terminals, verifying sensor accuracy, and confirming safeties and alarms. The visit ends with calibration and a performance run so setpoints, staging, and economizer logic match the actual load and local codes.

Which Furnace and Heating System Checks Are Essential for Fall?

For fuel-burning equipment, a technician verifies burner ignition, flame quality, and gas pressure. Combustion chambers are cleaned to stabilize the flame and improve heat transfer. The flue and venting are inspected to confirm proper draft and complete removal of exhaust. High-limit and rollout controls are tested, since those devices prevent overheating and protect occupants. Heat exchanger integrity is reviewed with light, mirrors, or approved instruments. These steps reduce carbon monoxide risk, raise steady-state efficiency, and help the system reach setpoint faster on cold mornings.

How Should Heat Pumps Be Maintained for Fall Efficiency?

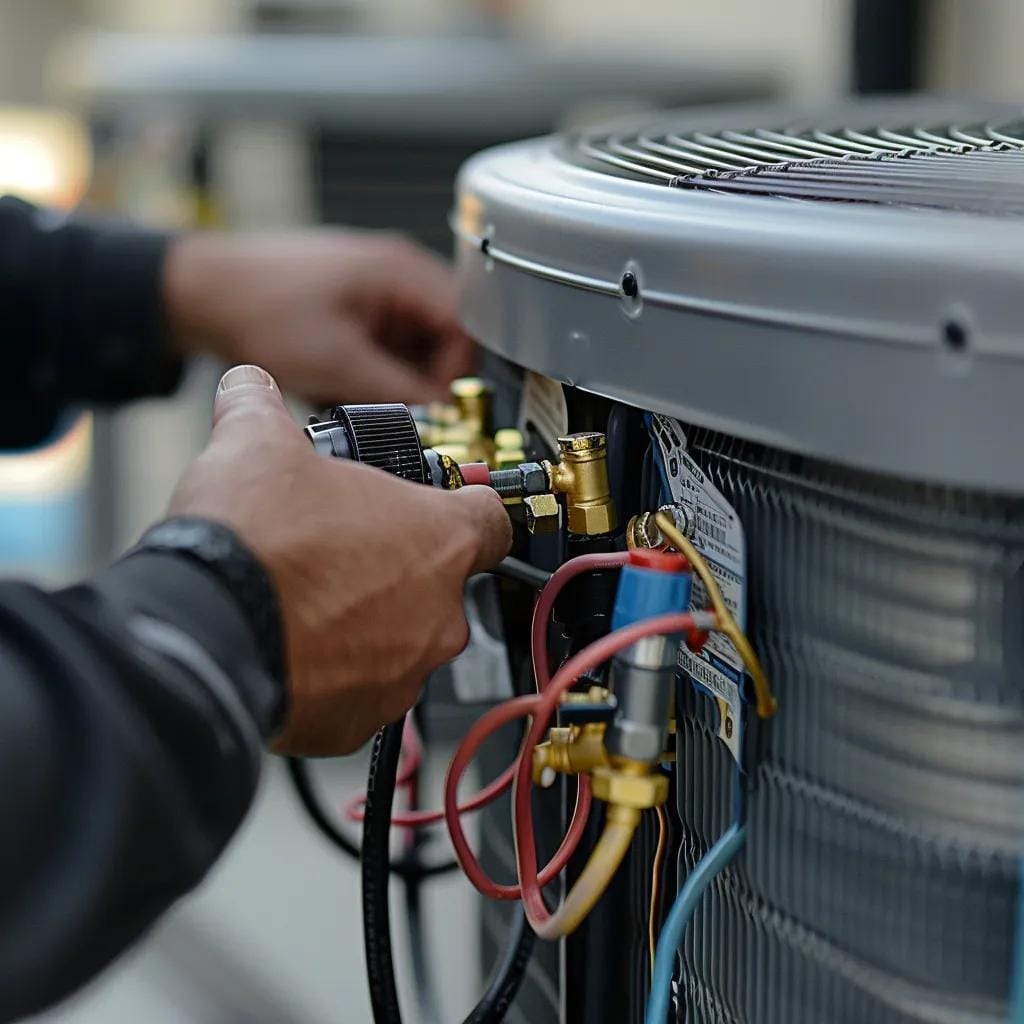

Heat pumps need targeted service as they move from cooling to heating. Correct refrigerant charge is essential, so pressures, superheat, and subcooling are compared to manufacturer specifications. Outdoor coils are washed and fins straightened so frost does not build prematurely. Defrost controls are exercised, sensors are checked, and the reversing valve is cycled to confirm smooth changeover. Technicians also inspect crankcase heaters, contactors, and fan motors. Done together, these tasks prevent nuisance defrost, protect the compressor, and keep capacity stable when temperatures dip.

What Role Does Air Filter Replacement Play in Fall HVAC Care?

Filters are the first line of protection for coils and blowers. Replacing loaded media before heating season preserves up to 90 percent of the system’s design airflow, which keeps supply temperatures consistent and reduces fan energy. Cleaner filters also limit particulate recirculation in occupied spaces, which supports indoor air quality goals during months when windows stay closed. In many buildings, setting a standing replacement cadence of 60 to 90 days, adjusted for occupancy and dust load, prevents pressure drop from creeping up and triggering comfort complaints.

Why Is Thermostat Calibration Important Before Winter?

Controls drive everything. If a thermostat or zone sensor reads high or low by a few degrees, the equipment will short-cycle or run too long. Calibrating sensors to within about ±1 °F, aligning heat and cool differentials with occupant needs, and confirming schedules for occupied and unoccupied periods prevent overshoot and trim utility spend. It also ensures boilers, furnaces, or heat pumps stage on in the intended sequence, which protects equipment life and avoids morning spikes. A brief controls check during fall service ties the whole tune-up together, turning clean hardware into predictable comfort and lower operating costs.

How Can Commercial Property Managers Perform DIY Fall HVACMaintenance?

Basic, low-risk checks can help you spot issues between scheduled service visits. For most buildings, the best place to start is with the areas you can see and reach without tools. Look at condensate drain lines and make sure water is moving freely. If you notice standing water, algae, or a musty odor near the air handler, the line may be restricted. Walk accessible duct runs and look for loose tape, missing mastic, or crushed sections that could leak air. Outside, clear leaves, grass, and trash from around rooftop or ground units so coils can breathe on cool, damp mornings. These simple steps take minutes and can prevent comfort complaints when temperatures swing.

What Simple Inspections Can Be Done Without a Technician?

Focus on airflow, controls, and obvious warning signs. Check the condition of return and supply filters and replace them if they look loaded or if the differential pressure indicator is in the red. Confirm that supply diffusers and returns are not blocked by furniture, boxes, or seasonal decor. From the thermostat or building automation system, run the equipment and listen. Rattles, grinding, or sharp squeals point to belt and motor issues.

A sour or burning smell at startup deserves attention. If you can read temperatures safely, compare the supply to the return at a single air handler. A heat rise or temperature split that is far outside the expected 15 to 20 degrees usually means airflow or firing rate needs adjustment. Record what you see and hear so a commercial HVAC technician can act on clear notes later.

When Should You Call a Certified HVAC Technician for Fall Service?

DIY checks are not a substitute for a licensed visit. Schedule a professional if you see frost or oil stains on refrigerant lines, repeated lockouts on the heat or defrost, or water around the air handler that returns after a simple drain flush. Uneven temperatures between zones, frequent short cycling, or a thermostat that drifts several degrees from a handheld thermometer also merit a call.

Any trace of flue backdraft, a tripped combustion safety, or a carbon monoxide alarm requires immediate attention. Technicians will verify gas pressure, test safeties, inspect heat exchangers, check electrical connections, calibrate sensors, and set economizer and staging logic so the system runs to specification.

What Are the Risks of Skipping Professional Fall Maintenance?

Deferring service pushes small problems into the busy season. Dirty burners and coils drive up energy use and stretch heat-up times. Loose lugs and aging capacitors can cause nuisance trips that shut down an air handler during peak demand. Bearings without lubrication wear quickly, which leads to noisy operation and, eventually, motor failure. Poor airflow from clogged filters or leaking ducts forces longer run times and raises bills month after month.

Most importantly, combustion systems that are not inspected can develop cracks or venting problems that put occupants at risk. A routine fall tune-up for commercial HVAC equipment catches these issues early, extends component life, and keeps indoor conditions steady as temperatures drop. Pair that visit with your in-house checks and a simple log of findings, and you will head into winter with fewer surprises, lower utility costs, and a building that stays comfortable for the people who rely on it.

How Do Smart Thermostats Improve CommercialHVACEfficiency in Fall?

Smart thermostats give you tighter control over heating during the shoulder season, when Atlanta mornings can be cool and afternoons mild. Instead of running fixed schedules, they read occupancy patterns, monitor outside air, and adjust setpoints in real time. That means earlier warm-up when a space is filling, deeper setbacks when it is empty, and fewer short cycles that waste energy. Because these devices are networked, facility teams can see status, alarms, and trends without leaving the desk. The result is steadier comfort and lower run time across your commercial HVAC equipment as temperatures start to drop.

What Features of Smart Thermostats Save Energy During Fall?

The biggest gains come from adaptive scheduling and verified setbacks. After a short learning period, the thermostat predicts when people arrive and leave, then preheats or relaxes the space only as needed. Remote access helps supervisors correct settings after hours, which cuts waste from accidental overrides.

Most models also generate simple energy reports that highlight zones that miss setpoints or run longer than expected. In many offices and light commercial buildings these controls trim fall heating costs by roughly 10 to 12 percent, mainly by reducing unnecessary cycles and tightening deadbands around occupied hours.

How Do Smart Thermostats Integrate with CommercialHVAC Systems?

Integration is straightforward when you plan it like any other control change. The thermostat communicates through BACnet or Modbus so it can share data with an existing building automation system. During commissioning, sensors are calibrated, zone dampers are checked for travel, and setback and recovery windows are matched to actual business hours.

Economizer logic is confirmed, so the system uses cool outdoor air on mild days rather than mechanical cooling. For heat pumps, the defrost strategy and auxiliary heat lockouts are verified so that electric heat does not come on early. A short operator walkthrough at the end locks in naming, trend logs, and user permissions, which prevents drift back to manual habits.

What Are the Cost Benefits of Installing Smart Thermostats in Fall?

Installing controls before the first cold snap captures savings for the entire season and avoids peak-season disruptions. A mid-size office or retail site often sees payback inside 18 months through lower fuel and electricity use, especially when morning warm-up and evening setbacks are enforced consistently. Remote diagnostics reduce service calls by flagging issues like stuck dampers, dirty filters, or erratic heat rise before comfort complaints reach the front desk.

Many utilities also offer rebates for connected controls, which shortens payback even further. Combined with routine fall maintenance on the commercial HVAC equipment itself, smart thermostats help you hold steadier temperatures, cut energy spend, and reduce wear on fans, compressors, and burners as the region moves into cooler weather.

What Are Common CommercialHVAC Problems in Fall and How to Prevent Them?

When cooling season gives way to heat, weak points in a system tend to show up fast. The most common issues are no-heat calls, noisy starts, random shutdowns, and uneven temperatures across floors or zones. Each has a fix that is simpler and cheaper when handled early. A furnace that will not light usually traces back to a dirty pilot assembly, fouled burners, a weak igniter, or poor draft through the flue.

Odd squeals or thumps often point to dry bearings, loose belts, or a fan wheel that needs rebalancing. Intermittent shutdowns are frequently tied to dirty coils that trap heat, a low refrigerant charge on heat pumps, or safety switches tripping because of blocked airflow. Add in clogged filters and miscalibrated thermostats, and you have a short list of why buildings see comfort complaints in October and November.

Preventive work is straightforward. Clean the combustion side, confirm gas pressure and draft, and check heat exchanger integrity. On heat pumps and packaged units, wash coils, verify charge with proper superheat and subcool readings, and test defrost operation. Replace filters, tighten electrical connections, lubricate motors where applicable, and confirm economizer and damper travel. A short controls review to correct schedules and setbacks for fall conditions rounds out the checklist. Tackling these items before the first cold snap keeps commercial HVAC equipment stable when loads increase.

Why Does My Furnace Fail to Start in the Fall?

Most no-start situations come down to fuel, air, or spark. If burners or the pilot assembly are dirty, the flame will be weak or unstable and the board will lock the cycle out. If the inducer cannot pull a proper draft because the vent is restricted, the pressure switch will keep the furnace from lighting.

Low gas pressure and a cracked or fouled flame sensor cause the same stop-start pattern. A tune-up that cleans the burners and pilot assembly, verifies draft, sets gas pressure to spec, and polishes or replaces the flame sensor usually restores reliable ignition. It is also smart to confirm the thermostat is calling correctly and that safeties like limit switches are not tripping due to poor airflow.

What Causes Strange Noises in CommercialHVAC Units During Fall?

Squealing and grinding sounds are classic signs of dry bearings or a belt that has lost tension. A thump at startup can indicate a loose blower wheel or debris in the housing after a long cooling season. Rattles often come from panel screws that backed out or duct joints that need resealing. During fall service, a tech will lubricate motors that are not sealed, set belt tension and alignment, tighten hardware, and true the blower wheel. Catching these mechanical issues early protects motors and bearings from heat and friction that shorten their life.

How Can Fall Maintenance Reduce Unexpected HVAC Breakdowns?

A thorough fall visit is about finding small faults before they strand a building to be without heat. Technicians look for pitted contactors, weak capacitors, and heat exchangers that show early stress. They measure amperage against nameplate values, confirm temperature rise, and compare supply and return deltas so airflow problems do not turn into cracked exchangers or frozen coils later. Controls are checked so stage sequencing and lockouts work the way the manufacturer intended. When these items are addressed ahead of peak demand, emergency calls drop, energy use falls, and comfort complaints fade.

Planned service with a consistent checklist gives property teams a clear record of work performed, parts replaced, and readings taken. That documentation makes it easier to spot trends, budget for replacements, and prove warranty compliance. Most important, it keeps occupants comfortable as the season changes. For managers responsible for multiple sites, building these steps into a standard fall program is the simplest way to keep commercial HVAC systems dependable through winter.

How to Choose the Right CommercialHVACMaintenance Partner in Metro Atlanta

Picking a maintenance partner for your commercial HVAC systems is a business decision, not just a service call. The right firm keeps tenants comfortable, protects equipment, and helps you meet code. Focus on proven competence, clear reporting, and dependable response, and you will avoid most of the surprises that drive up costs in peak season.

What Certifications and Experience Should You Look For?

Start with technician credentials. NATE certification shows core competency with heating, cooling, and air distribution. EPA Section 608 is required for refrigerant handling. OSHA training, typically 10 or 30 hours, indicates a baseline safety culture. Ask about factory training on the equipment you own, whether that is large rooftop units, boilers, heat pumps, or building automation. A strong partner can point to recent projects in office, healthcare, retail, or industrial settings and explain how those lessons apply to your sites.

Do not stop at badges. Request sample work orders and a recent preventive maintenance checklist. You should see measured data, not just “checked and OK.” At a minimum, look for recorded temperature rise, static pressure, motor amp draw, superheat or subcool when applicable, and a note on filter condition. Firms that track these numbers over time spot problems early and help you plan replacements instead of reacting to failures.

Why Are 24/7 Emergency Services Important for Commercial HVAC?

Buildings do not follow a nine-to-five schedule, and neither do failures. A partner with true round-the-clock coverage protects operations that cannot tolerate downtime, such as data rooms, medical suites, and busy kitchens. Ask how after-hours calls are handled, who answers, and what the average response time is. A firm that maintains local parts stock and service-ready trucks will often restore heat or cooling in one visit. Verify that they can coordinate cranes, lifts, and permits quickly for rooftop work, since delays there can stretch a simple repair into a long outage.

How Do Comprehensive Maintenance Plans Benefit Commercial Clients?

Well-structured maintenance plans do more than schedule seasonal visits. They standardize scope across sites, bundle labor and consumables, and lock in priority response. Look for plans that define tasks by season, list the readings that will be captured, and include coil cleaning, belt and bearing service, drain line clearing, combustion checks, and control verification. Good plans also set service level targets, such as response time and first visit resolution, and report performance against those targets each quarter. That level of structure makes budgeting predictable and gives you documentation for warranties and audits.

What Role Do Safety, Compliance, and Insurance Play?

Safety and compliance are nonnegotiable. Confirm that the firm carries general liability and workers compensation at levels appropriate for your properties. Ask how they meet the International Mechanical Code, NFPA 90A, and local permit rules, and how they handle lockout or tagout on energized equipment. Request their incident rate and a copy of a recent job hazard analysis. Vendors that take safety seriously protect your staff and your brand.

How Should Technology and Reporting Fit In?

Modern service should integrate with your building automation where possible, using BACnet or Modbus for trend logs and alarms. Expect digital service reports with photos, time stamps, and readings you can compare across visits. If you use a CMMS, ask about data exchange so work orders and asset history live in one place. Clear reporting turns maintenance into a tool you can manage, not a black box.

When and How Should You Schedule CommercialHVAC Fall Maintenance?

Getting fall service on the calendar at the right time keeps buildings comfortable, lowers utility spend, and cuts emergency calls when the first cold front arrives. Treat it like any other preventive task: plan ahead, verify scope, and lock in a slot before the rush. The guidance below applies across most commercial HVAC setups in Metro Atlanta.

What Is the Ideal Timeframe for Fall HVAC Service in Atlanta?

Aim for mid-September through early October. Daytime highs are still moderate, so you can test heat without stressing equipment. Scheduling in this window helps you avoid peak-season backlogs, keeps preferred time slots open, and gives your team room to address any repairs discovered during inspection. If your portfolio includes schools, medical offices, or 24-hour operations, book even earlier so corrective work can happen before heating demand ramps up.

How Often Should Commercial HVAC Systems Be Serviced?

For most properties, semiannual service is the baseline: cooling checks in spring and heating checks in fall. Sites with long runtimes, older equipment, or critical spaces often benefit from quarterly visits. That cadence catches belt wear, drain issues, control faults, and airflow problems before they turn into outages. Pair the visit schedule with monthly filter changes as needed for your MERV rating and dust load.

What Does a Typical Fall Maintenance Appointment Include?

A thorough fall visit focuses on safety, efficiency, and reliability. Expect technicians to verify burner operation and heat exchanger condition, clean combustion chambers, and confirm proper draft. Refrigerant circuits get checked for charge and leaks on heat pumps and packaged units.

Coils are cleaned, drain pans and lines are cleared, and blower assemblies are inspected, aligned, and lubricated where applicable. Electrical work includes tightening terminations, testing capacitors and contactors, and confirming motor amp draw against the nameplate. Controls are reviewed so that stage sequencing, economizer logic, and lockouts behave as designed. Finally, the tech should document temperature rise, supply and return deltas, and static pressure to confirm airflow is in spec.

How Do You Plan Around Operations and Tenants?

Coordinate with on-site teams to choose time blocks with the least impact. For offices, early mornings work well. For restaurants, mid-afternoon lull periods are typical. Communicate any short outages in advance and post temporary notices at elevators and lobbies if rooftop access is required. If a crane is needed, align permits and street access a week ahead to avoid delays. Multi-building portfolios should stagger visits so that at least one redundant system remains available in each critical zone.

What Documentation Should You Expect From Your Provider?

Insist on service reports with measured data, photos, and clear recommendations. You should see recorded temperature rise, static pressure, superheat or subcool when applicable, filter condition, and any corrective actions taken. Store these reports in your CMMS so you can trend readings, prove warranty compliance, and plan replacements. Good records make budgets predictable and reduce surprises.

How Can Indoor Air Quality Be Improved in Commercial Buildings During Fall?

Indoor air quality tends to slip in autumn as buildings tighten up and outdoor allergens linger. A focused commercial HVAC plan keeps air cleaner, occupants more comfortable, and productivity steady as temperatures drop.

What Are Common Fall Allergens Affecting Commercial Spaces?

Ragweed, grass pollen, and mold spores remain active well into the season. They enter on clothing, through loading docks, and via intake louvers. Once inside, they settle in carpets and duct interiors, then recirculate when fans cycle. Add higher occupancy after summer vacations and you get more CO₂ and odors competing with those particulates. Knowing these sources helps you target filtration and cleaning where it matters most: entrances, return air paths, and high density rooms.

Which Air Purification Solutions Are Effective for Fall?

Start with filtration. Where the equipment allows, upgrade to MERV 13 or better to capture fine particulates without pushing static pressure beyond design limits. Pair that with portable HEPA units in conference rooms and training spaces that see peak headcounts. UV-C at the coil surface limits microbial growth on wet fins and drain pans. Electronic air cleaners can help in facilities that struggle to hold higher MERV ratings, but they need regular maintenance to perform well. None of these tools replaces ventilation, so confirm the outdoor air settings in your economizers and verify that damper actuators and sensors respond correctly.

How Does HVAC Maintenance Enhance Indoor Air Quality?

A clean system moves and conditions air more effectively. Coil washing restores heat transfer and reduces the moisture film that supports mold. Drain pans and lines need disinfecting and clear flow to keep condensate from stagnating. Filters should be changed on schedule and seated correctly so air does not bypass the frame. Technicians should log total external static pressure, temperature differentials, and airflow to ensure the upgraded filters are not choking the system. Humidity control matters too; aim to keep indoor relative humidity near the mid 40s to limit dust resuspension and maintain comfort.

What Operational Policies Support Better IAQ In Fall?

Facility practices can reinforce what the mechanical system is trying to do. Use entry mats long enough to capture debris before it spreads through the building. Shift heavy vacuuming and floor care to after hours so particles settle before staff returns. Keep printer rooms under slight negative pressure and vent copy equipment to reduce ozone and VOCs. Review clean desk policies so custodial teams can wipe down more surface area each night. For buildings with variable occupancy, enable demand control ventilation with calibrated CO₂ sensors to bring in outdoor air when and where it is needed.

How Should You Monitor and Verify Results?

Do not guess. Trend CO₂, temperature, and humidity at the building automation system and spot check with handheld meters in problem zones. Track filter pressure drop so you replace media based on performance, not just the calendar. If complaints spike, commission a short IAQ assessment that includes particulate counts and a look at outdoor air delivery. Clear records make it easier to tune the commercial HVAC program each fall and prove that the system is supporting health as well as comfort.

Conclusion

Proactive fall maintenance is the key to keeping your commercial HVAC system running efficiently through the cooler months—preventing costly breakdowns and ensuring optimal indoor air quality for employees and customers. At Ace Tech Heating & Cooling, our certified technicians provide comprehensive commercial HVAC services tailored to your business needs. Schedule your fall tune-up today by calling (404) 369-9100 or requesting a free quote online—and experience the peace of mind that comes with a well-maintained HVAC system.